More Information

(+91) 9898994495 | 96

Membrane Nitrogen

- Home

- Project

- Membrane Nitrogen

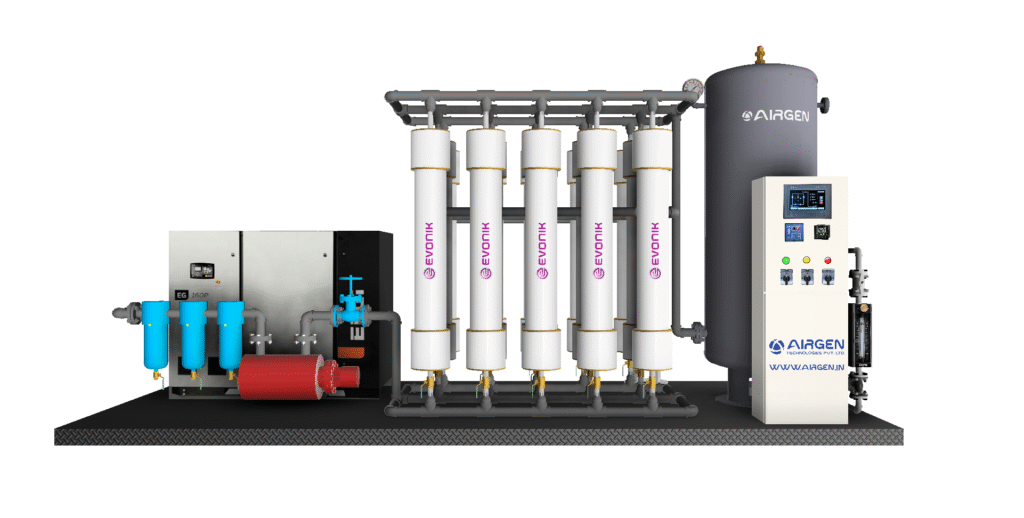

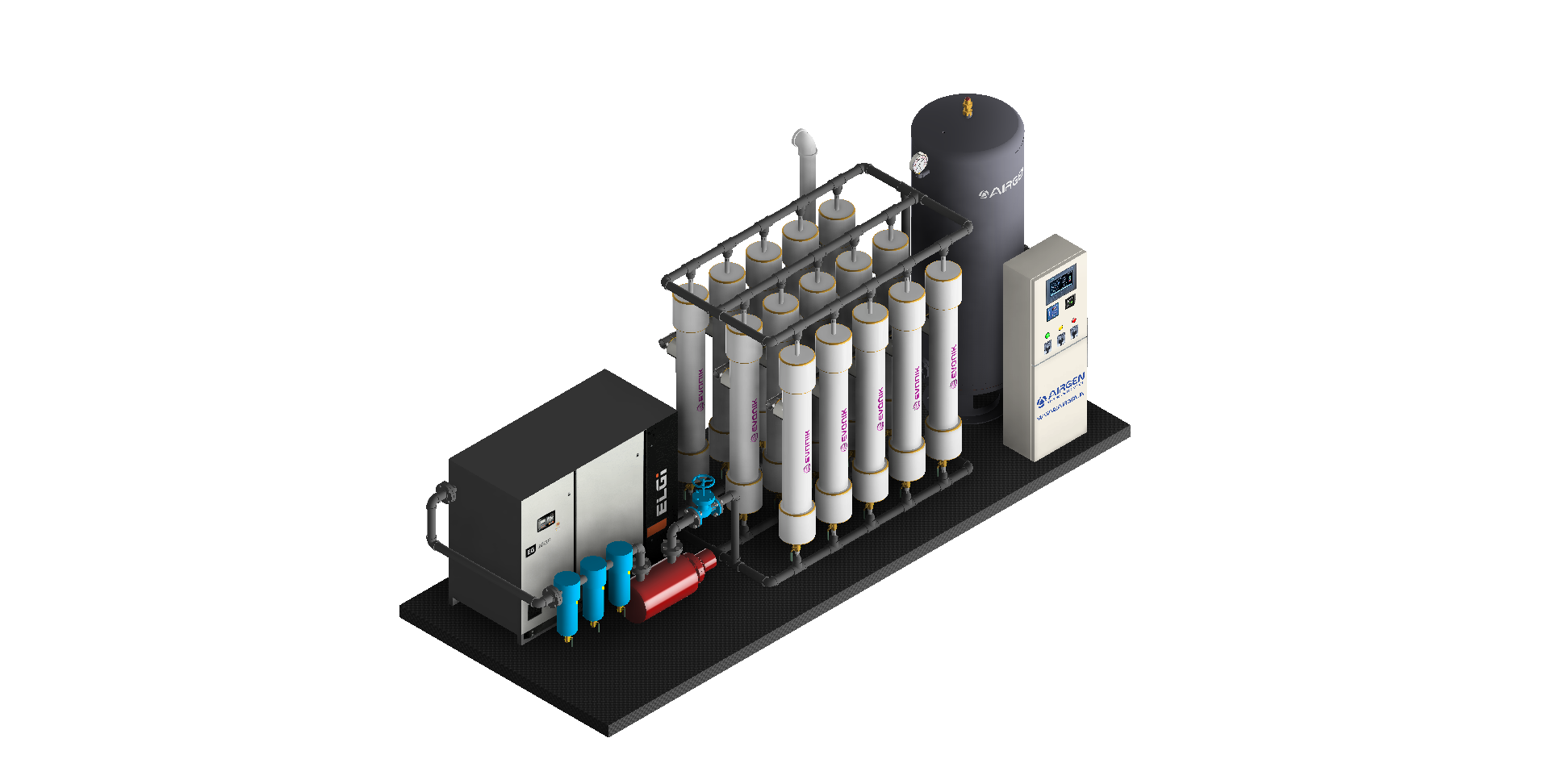

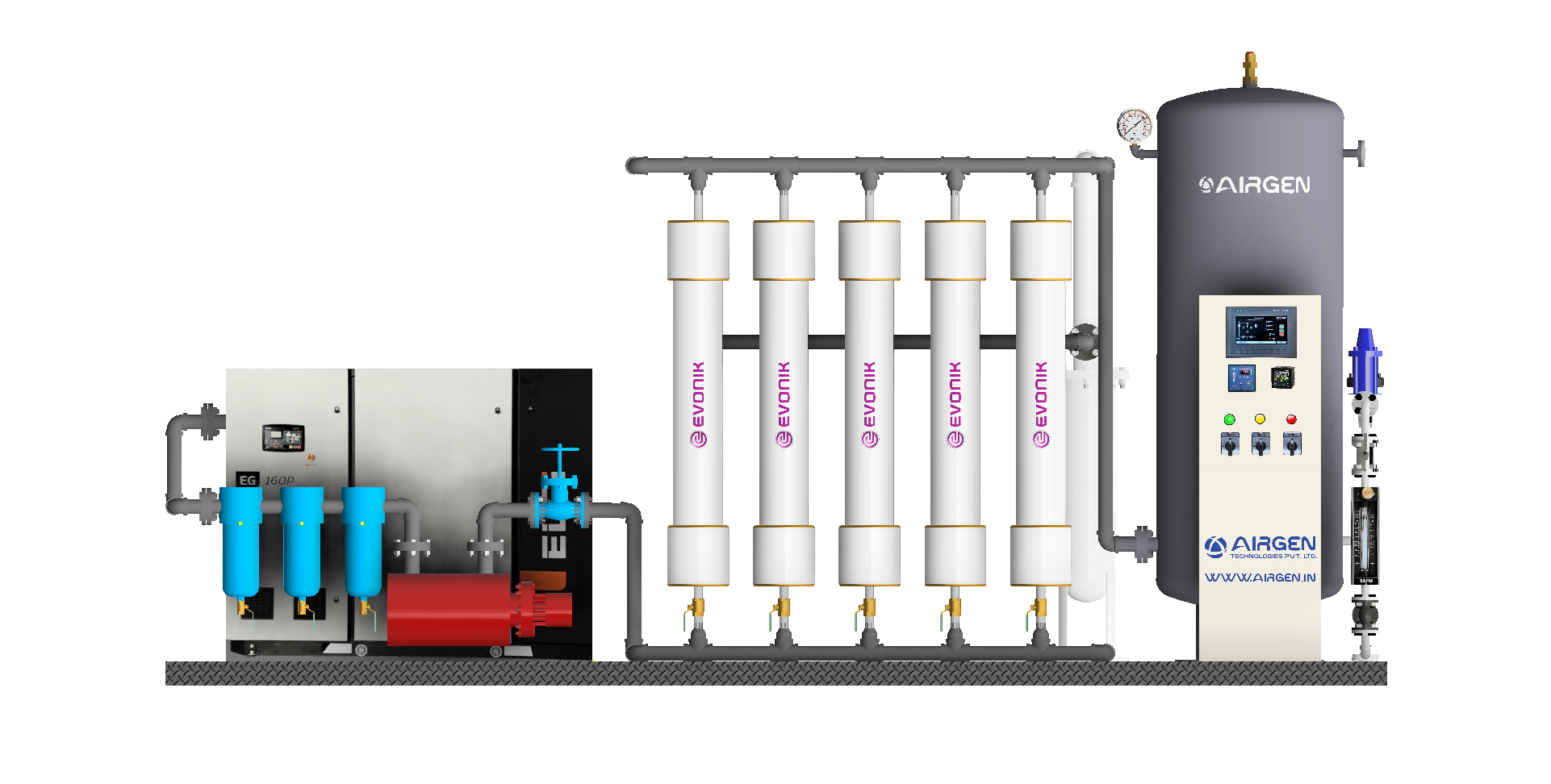

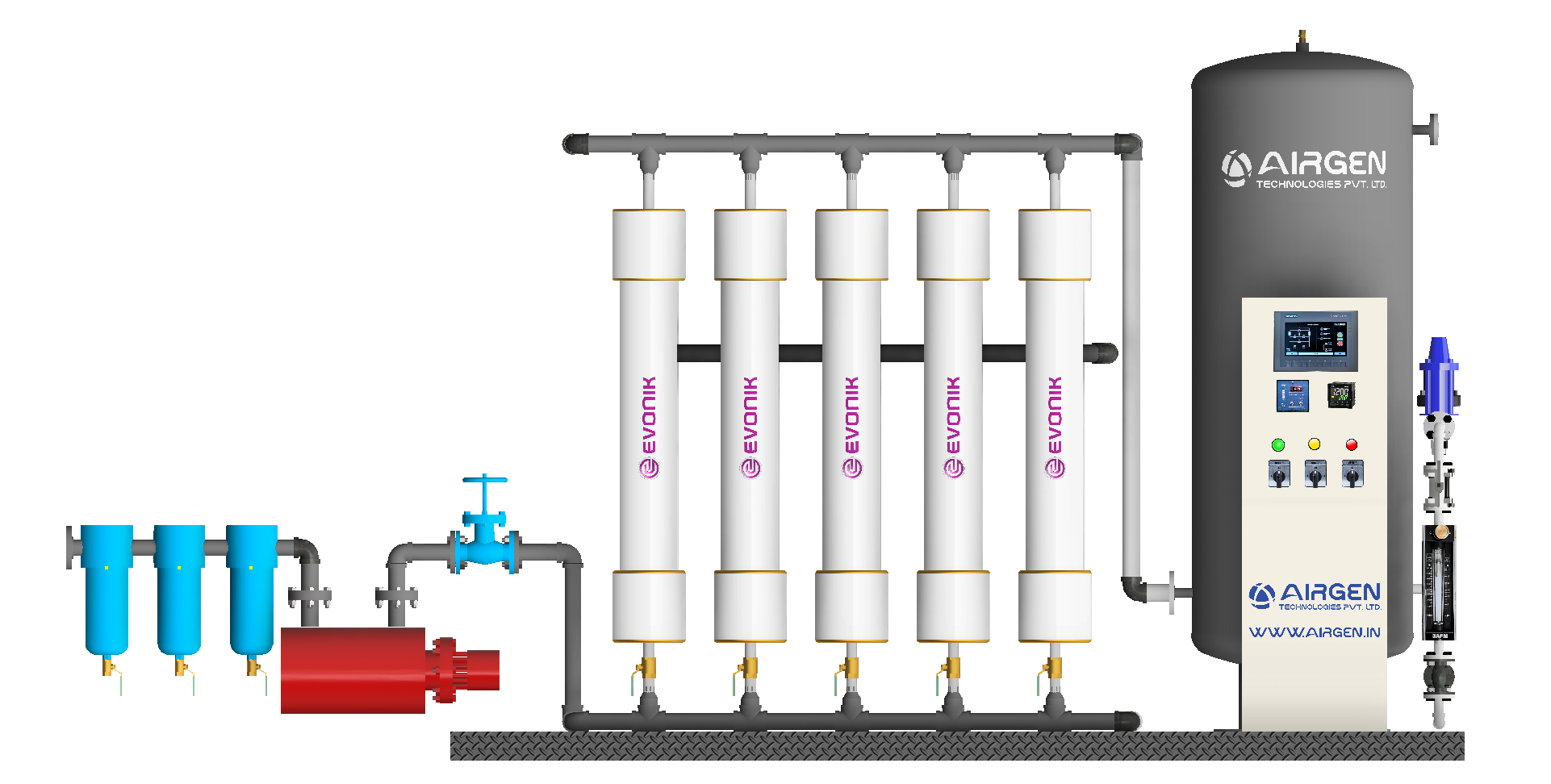

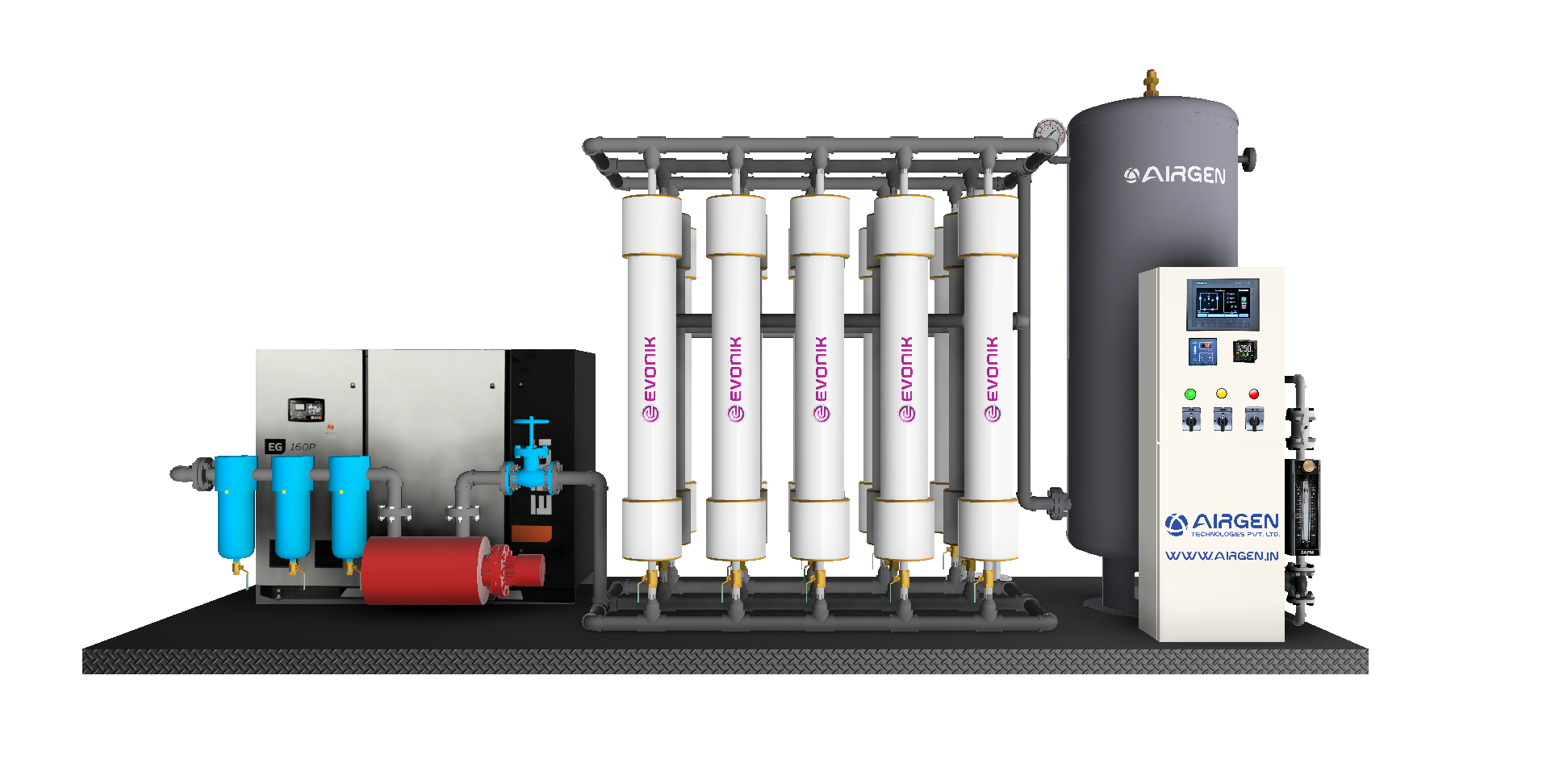

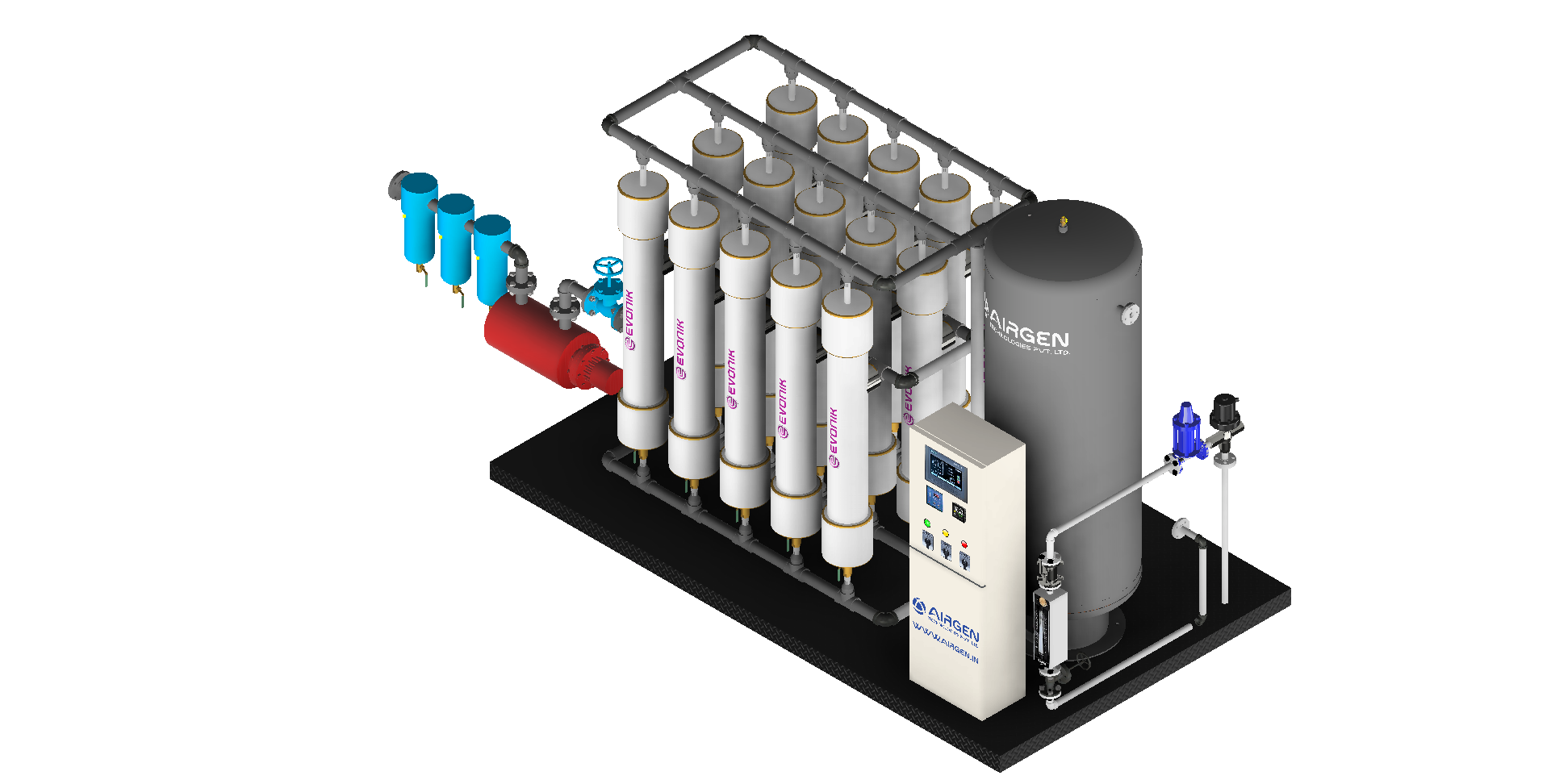

AirGen Technologies offers advanced Membrane Nitrogen Gas Generators designed for high efficiency, compact , and consistent performance. Our systems are built for industries that need nitrogen purity ranging from 95% up to 99%

Whether you require a continuous nitrogen supply for a critical process or want to cut down cylinder dependency, AirGen Membrane Generators deliver an on-site solution that’s clean, quiet, and virtually maintenance-free.

How Membrane Nitrogen Generators Work

Clean Air Intake

Ambient air is first compressed and filtered to remove moisture, oil, and particles.

Membrane Separation

The clean, dry air passes through hollow fiber membrane modules. These fibers selectively allow oxygen, water vapor, and other gases to diffuse out, while nitrogen continues through the membrane.

Pure Nitrogen Delivery

The resulting nitrogen gas is delivered at the required purity and flow rate, stored in a buffer tank, and made available on demand.

Product Highlights

- Purity: 95% to 99% nitrogen

- Flow Rate: 1 Nm³/hr to 500 Nm³/hr

- Pressure: 5 – 10 bar (adjustable)

- Plug & Play: Simple to install and start using with a compressed air supply

- Maintenance-Free: No moving parts = no operational hassle

- Compact & Mobile: Skid-mounted for easy installation

Advantages of Membrane Technology

Energy Efficient

Lower air-to-nitrogen ratio compared to traditional systems in low-purity applications.

Quick Start-Up

Generates usable nitrogen within minutes of startup—for on/off operations only.

Low Maintenance

No adsorbent media, valves, or purge losses—cut maintenance costs drastically.

Is Membrane Right for You?

Membrane nitrogen generators are ideal when:

- Your nitrogen purity requirement is 95% to 99%

- Your application includes:

- Beverage bottling

- Electronics manufacturing

- Laser cutting (for low-purity use)

- Inerting and blanketing

FAQ

General Question

Our membrane units deliver nitrogen purity from 95% to 99%, depending on flow and pressure settings.

Membrane systems are simpler for Low Purity use only. However, PSA systems offer higher purities (up to 99.999%) and are better for critical or high-purity industrial needs.

Minimal. Only pre-filters need regular servicing. No desiccant replacement.

Yes, it’s plug-and-play. Just connect a clean air line and power supply