More Information

(+91) 9898994495 | 96

PSA Oxygen Generator

- Home

- Project

- PSA Oxygen Generator

Breathe Better, Perform Better, Achieve More

AirGen Technologies is a leading manufacturer of PSA Oxygen Plants. Our plants are designed to produce oxygen gas with purity ± 93 % Since our inception, we have been offering a comprehensive range of PSA oxygen plants of the highest purity to our valuable clients thereby attaining complete customer satisfaction. Owing to high quality medical grade oxygen, friendly operations, low maintenance and less operation cost, our PSA oxygen plants are widely used in industries such as hospital, health care, medical. All our PSA Oxygen plants are manufactured using the highest quality raw materials, world class technology and advanced manufacturing processes as per the set industrial norms.

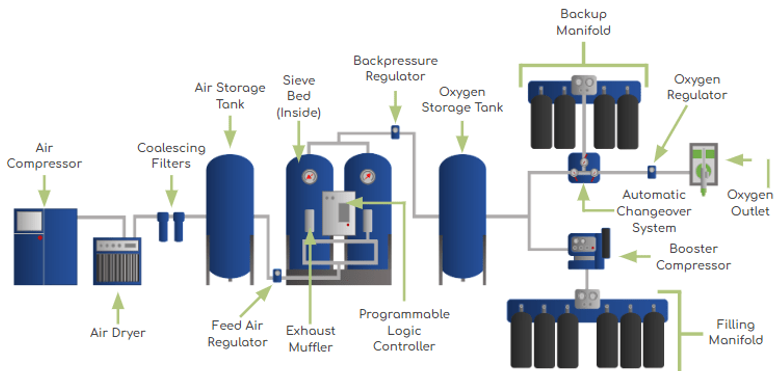

Working of PSA Oxygen generation plant work

Air Intake and Preparation

Airgen Technologies’ PSA oxygen plants provide a reliable and economical solution for on-site oxygen generation.We start by drawing in ambient air, which is then compressed and passed through a series of filters and dryers. This step removes moisture, dust, and other impurities, ensuring that only clean, dry air enters the system.

Separation

The system draws in ambient air—which contains about 78% nitrogen and 21% oxygen—and uses advanced zeolite-filled towers to selectively trap nitrogen. As nitrogen is adsorbed, oxygen with up to 93% purity flows through and is collected in an oxygen surge tank. The plant uses two towers working in cycles: while one separates oxygen, the other regenerates by releasing trapped nitrogen. This ensures a continuous, efficient, and maintenance-friendly oxygen supply to Store

Oxygen Storage & Deliver

The produced oxygen is collected in a Storage tank, maintaining steady pressure and purity levels. From here, Oxygen gas is continuously available to your process. This results in significant energy savings & Fast result.

Oxygen Gas Generator Plant

- Capacity/Flow rate: 1 Nm³/hr to 100 Nm³/hr (customized flow rate is available)

- Nitrogen purity levels: Up to ± 93%

- Pressure range: Up to 5.0 bar(g) standard; higher pressures will be available on demand with our pressure booster systems

- Dew point: Up to -40°C

- Ideal modular designs: Facilitates easy installation, space optimization, and mobility

- Smart operation: Comprises of PLC-based control systems that makes it user-friendly

System Specification

AirGen offers complete turn-key system that includes the consultation, service and support in all aspects of customer’s air requirement. At each stage of the business order process starting from the enquiry to the stable running of plant, our technical teams work directly with our clients to specify and install systems to their exact specifications. AirGen has a very good and experienced service team ready for 24 / 7 to answer any question the customer may have.

Advantages of AirGen PSA Oxygen Plant

1 . One Solution for Multiple Challenges

Airgen’s PSA system is your all-in-one oxygen infrastructure: it handles cylinder limitations, minimizes oxygen wastage, reduces noise during cylinder handling, and eliminates the need for extra staff to manage supplies.

2. Maximized Savings

By enabling on-site oxygen production, hospitals can reduce dependency on costly liquid oxygen and cylinder refills. Many facilities save up to 65–70% on oxygen costs compared to traditional cylinder supply models. This aligns with global case studies showing cost reductions of 30–40% or more.

3. Eliminate Supply Risk

With oxygen generated directly on-site, Airgen systems ensure uninterrupted supply—no more delays or disruption due to delivery or external vendor dependency.

4. Consistent Medical-Grade Purity

Our PSA plants consistently deliver oxygen at 93% ± 3% purity, fully compliant with pharmacopeia standards. Continuous purity monitoring ensures patient safety and regulatory compliance.

5. Enhanced Safety

Airgen’s PSA systems remove the hazards associated with high-pressure cylinder storage and cryogenic tanks, significantly improving safety within hospital premises.

6. Autonomy & Efficiency

Produce exactly what you need. Airgen systems operate 24/7, give full autonomy to health centers, and adapt to actual consumption—maximizing efficiency and minimizing waste.

7. Reliable, High-Performance Operation

Designed for round-the-clock use, Airgen plants deliver stable medical oxygen flow with constant pressure and high capacity—ensuring uninterrupted patient care even under peak demand.

8. Compact Footprint

Airgen units are engineered for space efficiency—they can be installed on rooftops, in equipment rooms, or hospital halls without requiring a large footprint.

FAQ

Frequently Asked Questions

Our PSA plants consistently deliver medical-grade oxygen at 93–95% purity (±3%), fully compliant with WHO and Pharmacopoeia standards.

With Airgen, you save significantly. On-site production eliminates recurring delivery, rental, and logistics costs—making it far more economical, especially for continuous use.

These systems are fully automatic and skid-mounted—simply “plug it in, turn it on, and count on it.” They boast a strong performance record with minimal maintenance needed

Thanks to their modular design, Airgen plants fit easily in compact spaces like rooftops, corridors, or service areas, with no need for extensive safety clearance.

Absolutely—when correctly sized and well-maintained, an Airgen plant removes dependency on cylinders. Still, keeping a small backup cylinder for emergencies or during maintenance is wise.

Most facilities recover their investment within 12 to 24 months, depending on plant capacity and existing oxygen supply costs.