More Information

(+91) 9898994495 | 96

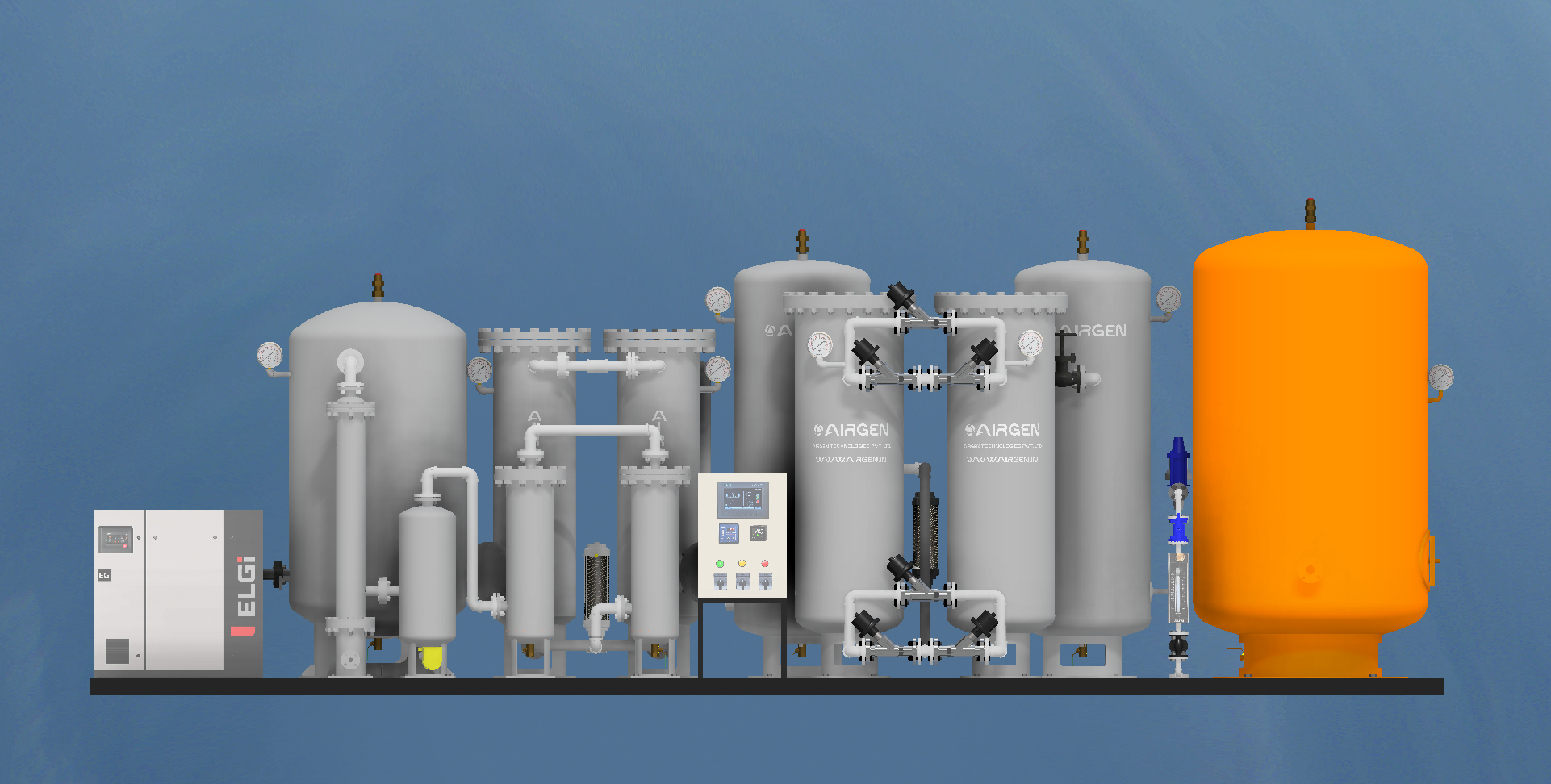

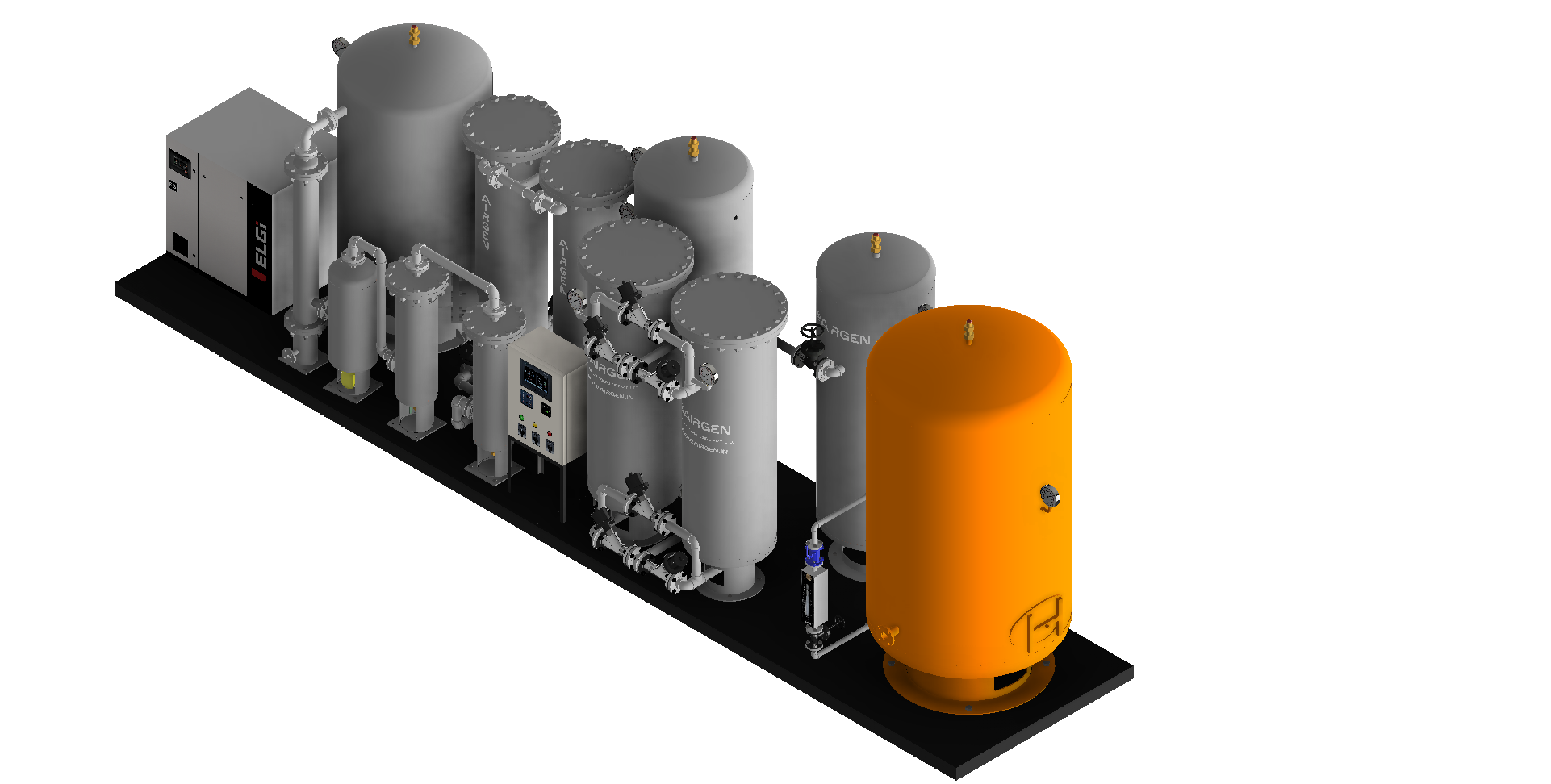

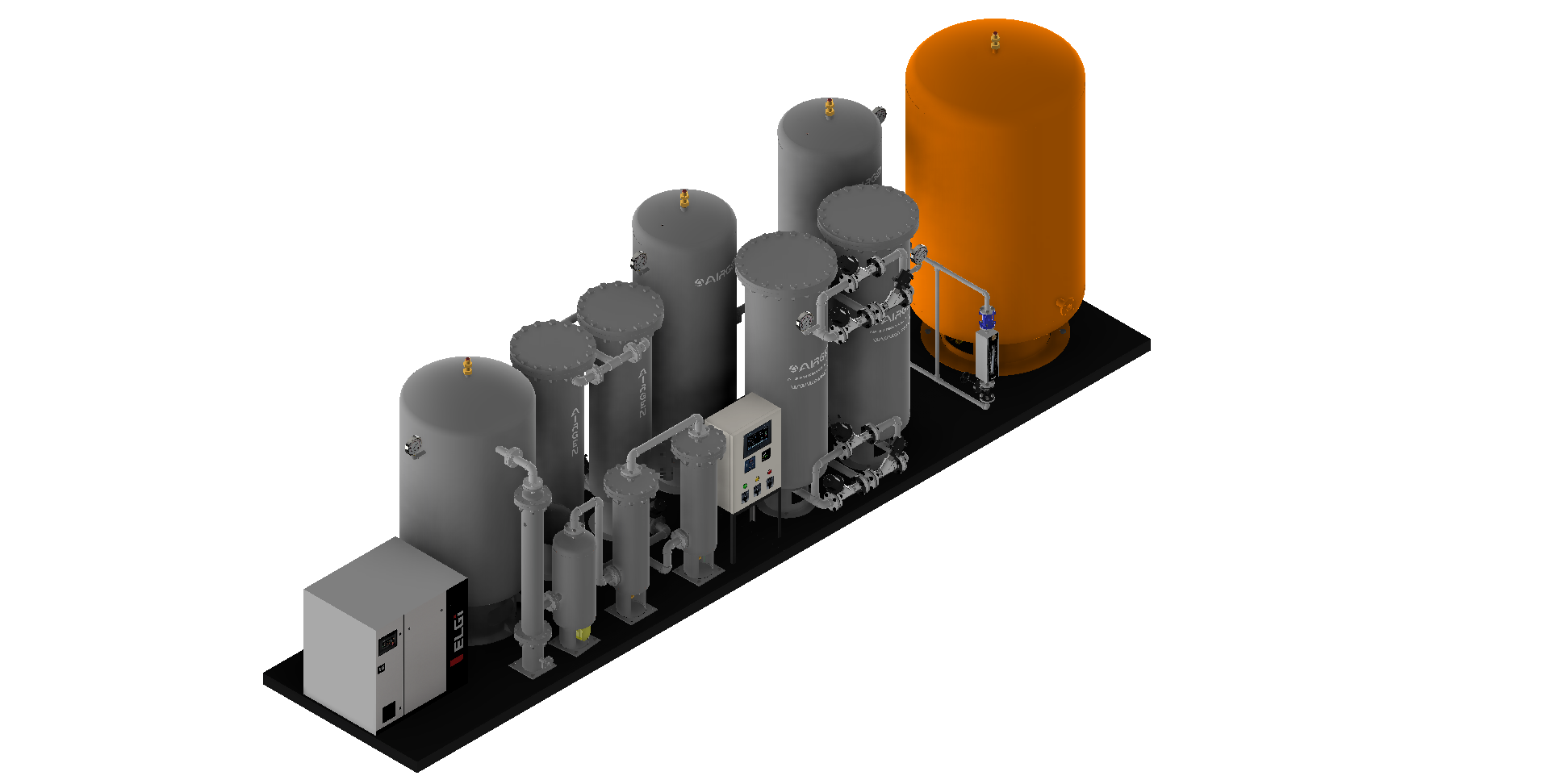

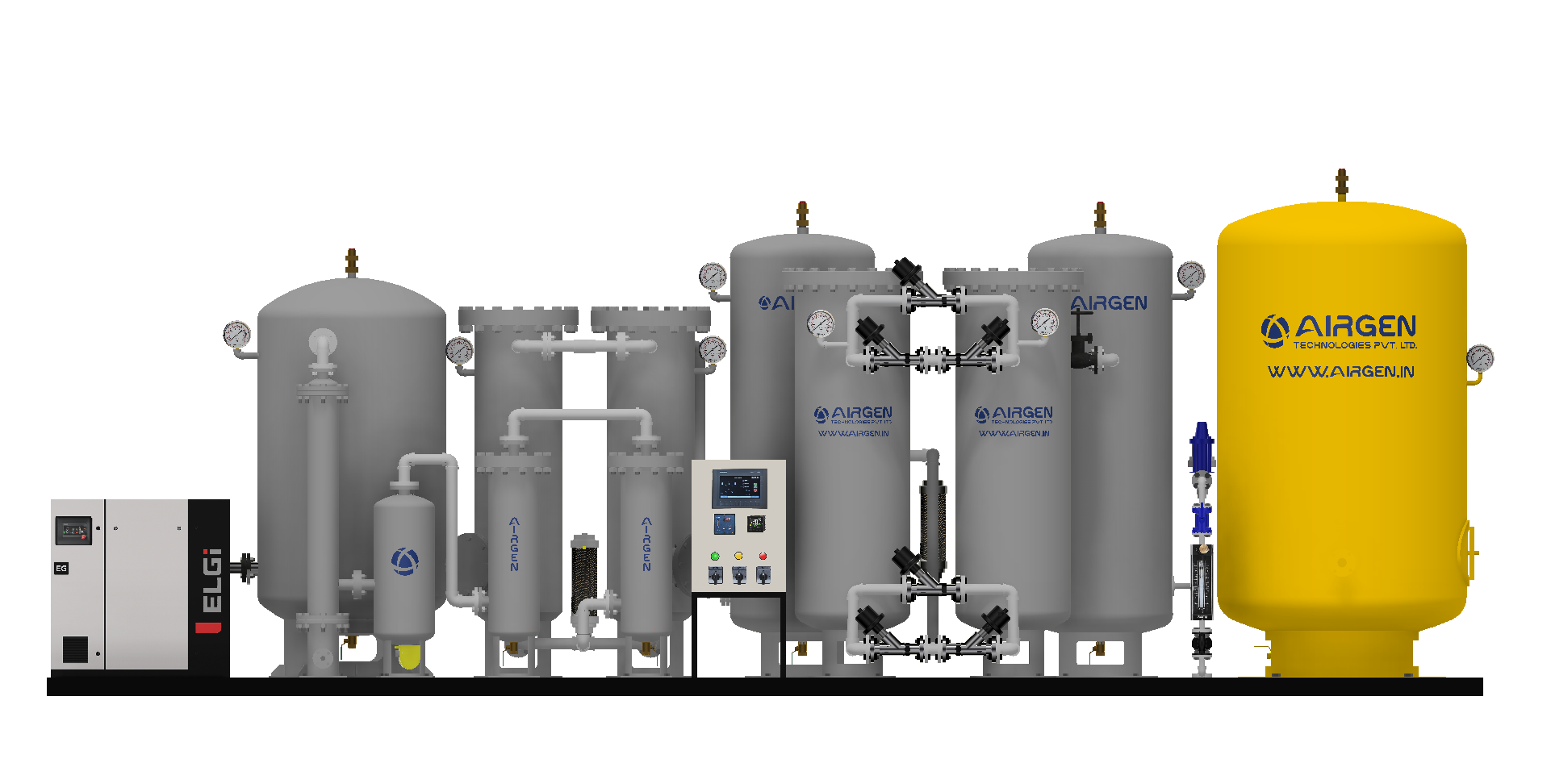

PSA Nitrogen Generator

- Home

- Project

- PSA Nitrogen Generator

“Empowering your business with best air quality, performance and solutions”

AirGen Technologies is a primary manufacturer of PSA Nitrogen gas generation Plants. The plant we manufactures are designed to produce nitrogen gas with purity in an impressive range from 99% to 99.999%. AirGen manufactures high-performance, cost-effective and efficient nitrogen gas generators to serve a large group of different applications. PSA Nitrogen Gas Generators facilitates in meeting the onsite gas generation requirements simultaneously eliminates the reliability on traditional methods of nitrogen supply and storage that are also expensive & hard to care.

We believe in providing an efficient solution with least operating costs and superb air purity. With this belief and continuous effort in improving our product design and performance, we have earned the valuable trust of our customers. They are getting their exact requirements of air consumption with the desired flow and purity which is all the users and the suppliers both wants to achieve.

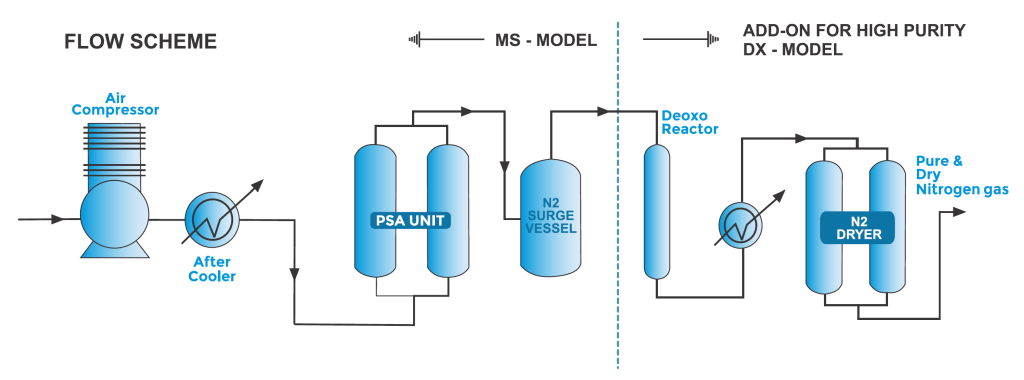

Working of PSA Nitrogen generation plant

By adopting the advanced Pressure Swing Adsorption (PSA) technology, we at AirGen, transform ordinary air into high-purity nitrogen through. This technology comprises of sequential steps described below.

Air intake and reparation

In this initial process, ambient air (that is mixture of oxygen, nitrogen and other gases) is drawn, compressed and then goes through a series of multiple filters and dryers. This step removes moisture, dust, and other impurities, ensuring that only clean and dry air enters the system.

Separation

This is the fundamental step of PSA nitrogen gas generation process. As the name suggests, this step separates the nitrogen and oxygen gas. Let’s understand how this happens.

The purified air flows into vessels filled with Carbon Molecular Sieve (CMS). Here, oxygen molecules are adsorbed onto the CMS pores due to their smaller size, while nitrogen molecules, being larger, pass unaffected. To provide an uninterrupted nitrogen supply, our system uses two different adsorption vessels that alternate between adsorption and regeneration phases. When one vessel is separating nitrogen, the other is releasing the previously adsorbed oxygen back into the atmosphere. Similarly, when second vessel separates the nitrogen,

first one releases oxygen. This is a continuous cycle that ensures continuous supply of nitrogen at the application place.

Nitrogen collection and supply

The nitrogen produced is stored in a Storage tank with maintained steady pressure and purity level. This stored nitrogen is continuously supplied to the end requirement in the controlled amount.

FAQ

Frequently Asked Questions

Our PSA (Pressure Swing Adsorption) systems deliver ultra-high purity nitrogen ranging from 95% up to 99.999%. Oxygen content can be as low as 1 ppm, and the dew point can reach −80 °C depending on model and configuration.

Absolutely. We manufacture each nitrogen generator based on your specific purity and flow requirements, ensuring a custom-fit solution for your operations.

Airgen offers a wide spectrum of models—from laboratory units delivering 2–5 Nm³/hr to industrial-grade systems producing up to 1,500 Nm³/hr.

Yes. All our nitrogen generators are designed to meet Food‑Grade and Pharma‑Grade standards (FDA/ISO), delivering ≥ 99.5% purity suitable for these sensitive industries.

Our PSA units typically operate on 220 V single‑phase (50/60 Hz) and consume only 0.2–0.4 kW per unit. Note: compressor power varies as per system capacity.

Airgen systems are engineered for low-noise operation—measuring under 75 dB(A) at 1 meter—with efficient silencers in the exhaust line for near-silent service.

Not continuously. Once commissioned, Airgen nitrogen generators run unattended, with integrated sensors and control systems ensuring seamless operation.

We integrate online oxygen analyzers to continuously monitor nitrogen purity. If purity drops below the set threshold, the system shuts down automatically and triggers an alert.

Yes. All Airgen units arrive pre‑assembled on a robust steel frame. Installation requires simply connecting power and compressed air. We also provide on-site commissioning support by our engineer team.

Every 6 months: Replace inlet pre-filters/coalescers, clean towers, and inspect gauges & pipework.

Every 2–3 years: Perform advanced service, including adsorbent regeneration/replacement, valve checks, and sensor calibration (depending on operational hours).

Full instructions are detailed in the provided Operation & Maintenance Manual.

Our high-quality sieves typically last 10+ years, often enduring the full life of the unit. To maximize lifespan, ensure oil‑free air via lubrication‑rated pre‑filters and timely replacements.

The system is designed for 24/7 operation. In low-load conditions, nitrogen pressure builds in storage tanks, triggering an automatic shutdown cycle. As pressure drops during use, it restarts automatically—maintaining optimal uptime.

Airgen systems are cost-effective. The only operating cost is the compressor’s electricity—typically around ₹4 /m³ of nitrogen produced. This is highly economical compared to cylinder nitrogen at ₹60 /m³. Many customers achieve payback in just 1–2 years.

With routine maintenance, our generators offer a reliable service life of 15 years or more